Text José Silva | Translation Jani Dunne

Portugal is the greatest producer of corks (for bottles) in the world, as well as one of the biggest producers of cork.

Portugal is one of the biggest producers of cork – Photo by José Silva | All Rights Reserved

The relationship wine has with corks is self-evident and, although attention has been drawn to other materials, cork corks are still the reference when it comes to sealing bottles. Furthermore, producers all around the world have gone back to using cork tops as a result of the enormous development in the quality of this raw material.

The Raw Material – Photo by José Silva | All Rights Reserved

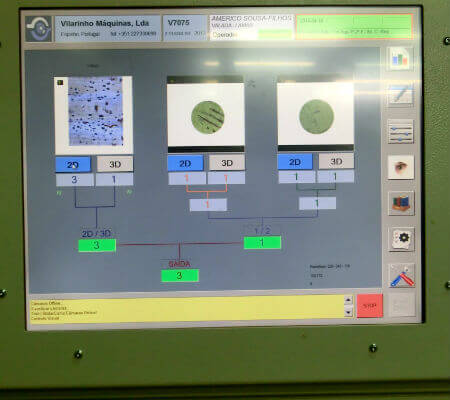

High-End Technology – Photo by José Silva | All Rights Reserved

Some production units in Portugal have invested in high-end technology, which means corks of much higher quality and a big drop in production costs, which ultimately helps companies make a profit.

AS-Cork – Photo by José Silva | All Rights Reserved

This is the case with AS – Cork (Américo Sousa & Filhos Lda.), whose headquarters are in Santa Maria de Lamas. The company’s development has been steady, relying on a very well programmed investment policy based on the market’s demands. This growth brought them to invest in the Moroccan market, where their production unit has proven quite successful.

The family that own the company are local and have been connected to the cork industry for a long time. Two brothers dedicate their full schedule to the three factories, located quite close to each other.

The raw material is then selected, cut and stored – Photo by José Silva | All Rights Reserved

In the first factory, they receive the raw material, which is then selected, cut and stored. The selection process is a careful one, where any unsuitable cork will be separated.

The Cork is Disinfected Using Several Processes That Involve Boiling – Photo by José Silva | All Rights Reserved

Then, the cork is disinfected using several processes that involve boiling in appropriate machines.

Cork Shavings – Photo by José Silva | All Rights Reserved

First Stage of Cork Production – Photo by José Silva | All Rights Reserved

Once dry, it is moved for the first stage of cork production, which will carry on in the second factory.

In the meantime, and maintaining quality control throughout the process, the cork shavings and the damaged cork, which cannot be used to produce corks but may be used for other purposes, are removed and sold to factories for other cork products – for decoration, for insulation, cork ballast, etc. They leave nothing to waste.

Maintaining Quality Control Throughout The Process – Photo by José Silva | All Rights Reserved

Cork Discs – Photo by José Silva | All Rights Reserved

In the second factory, quality control continues with the help of modern equipment, which allows for some innovation, whether in the production process or in the final products, such as cork discs – this company’s specialty – used to produce corks for sparkling wine and champagne. These are in high demand, and are sold to other units, seeing as that type of cork is not widely produced in Portugal yet.

This Fully Automated Unit Prioritises Cleaning – Photo by José Silva | All Rights Reserved

More and More Sophisticated Machines – Photo by José Silva | All Rights Reserved

This fully automated unit prioritises cleaning, in order to make contamination impossible. Machines are more and more sophisticated; using cameras and even laser beams, they can read in 2D and 3D, and are highly profitable and very efficient.

Extremely Well-Equipped Lab – Photo by José Silva | All Rights Reserved

A Specialised Team Tests Every Type of End Product – Photo by José Silva | All Rights Reserved

In the extremely well-equipped lab (which includes a chromatograph), a specialised team tests every type of end product, based on strict guidelines. No mistake can be made – one of the company’s principles.

The Third Factory – Photo by José Silva | All Rights Reserved

The third factory buys all the production off the first two and later sells it to countless clients – mostly foreign.

The Factory Where the Corks Are Finished- Photo by José Silva | All Rights Reserved

This factory is where the corks are finished, as per the client’s order, whether national or foreign.

Another Laboratory Continues the Quality Control – Photo by José Silva | All Rights Reserved

Another laboratory continues the quality control, ensuring all Health & Safety guidelines are met, and according to international law.

The Finished Corks Are Dispatched – Photo by José Silva | All Rights Reserved

Finally, the finished corks and cork discs are dispatched. This stage also involves using packaging that ensures the end product is protected until it reaches its final destination. A few months or even years later, we will surely find many of these corks when unwrapping wine bottles of various origins, even if this means one of the greater French champagnes.

A genuinely Portuguese product produced in line with the best products in the world.

Leave a Reply